Steel is an alloy of iron that is mixed with carbon which improves its strength and durability. Combine these properties with its low cost and you have a perfectly-suited alloy for a multitude of uses in various end applications, including (but not limited to) automotive, infrastructure, and appliance/HVAC.

Enter the role of steel processors. Steel processing companies like Nam Kim Steel provide manufacturers with the right steel material for their industry. This article will focus on the topic of steel slitting and how the slitting process works.

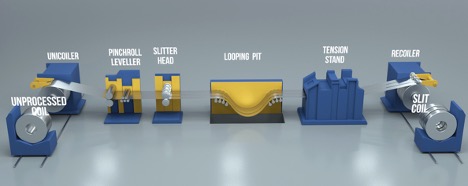

Steel slitting is a steel manufacturing process wherein a coil of steel is slit into the lengths and widths specified by the end application. This process requires machinery lines equipped with a decoiler, slitter, and a recoiler — to achieve the end product: slit steel coils, or “mults.”

An operator will feed the steel coil onto the uncoiler mandrel. The uncoiler unwinds the master coil, feeding it into the slitter head where the steel will be slit into narrow mults (strips) by rotary knives. The operator then inspects the individual mults to ensure the gauge width and edge condition meet required specifications. The mults will then travel through a looping pit to insure stress-free and camber-free recoiling of the slit material. Individual mults are then banded and packaged to specific customer requirements.

If you want to import GOOD QUALITY slitted Steel coil from Vietnam, please contact us at:

– Email: datdq@namkimgroup.vn

– Mobile/Whatsapp/Wechat/Line/Viber: +84 973 765 730

– Website: https://steelvn.vn/

Top VietNam Steel manufacturers I Slitted Steel coil manufacturers I Steel manufacturers & suppliers