Best Galvanized, Galvalume, Pre Painted Steel Sheet manufacturers from Viet Nam

Prime Hot Dipped Galvanized Steel Sheet in Coils (HDGI)

Detailed Product Description:

Capacity: About 85,000 Tons Per Month Width: 914 mm-1250mm or Slitting Width 70 mm – 900mm

Grade: SGCC, DX51D,CS, Gr Coil ID: 508mm/610mm

Zinc Coating: 60g/m2-350g/m2 Thickness: 0.2mm-4.0mm – All Available

Brand: NAMKIM STEEL Spangle: Regular/minimize Spangle

Usage: Constructions Coil Weight: 2-25MT

Payment: T.T Or Lc At Sight Delievery: By Container Or By Bulk.

Certificate system: ASTM, JIS G3312, BIS( Indian market ), SIRIM( Malaysi market ), SNI( Indonesia ), SASO( Saudi Arabia ), AS( Australia, ISO9001:2008, Eurocodes.

Technique: Technology: NOF (Non-Oxydizing Furnace), chormated, unoiled, various spangle, hot dipped

Package: Waterproof paper + polyethylene rush inhibitor, the antirust paper , the ring of defends on inside and outside, steel belt, and the guard plate. We can also pack according to your request details.

Dominant characteristics:

– Especially produced for various usage purposes

– Long life of 4 times longer than other normal

– Effective corrosion sheets

– Good heat resistance

– The anti-finger layer is equipped:

– Stain-proof and oxidization resistance

– Keeping the surface of the products shiny for a long time

– To reduce cracking, scratching coating during stamping, rolling.

Applicant:

Hot dip Galvanized steel coils are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per squaremeter.

See more: How To Find Metal Suppliers In Vietnam?

Galvalume Steel Sheet in Coils

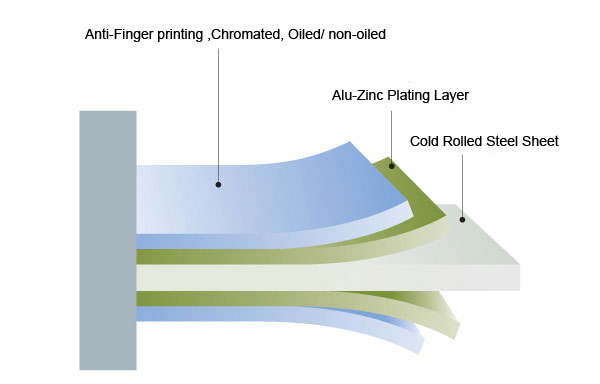

The galvalume & aluzinc steel sheet in coil uses the cold-rolled steel sheet as a substrate and solidified by 55% aluminum, 43.4% zinc and 1.6% silicon at 600 °C. It combines the physical protection and high durability of aluminum and the electrochemical protection of zinc. It is also called aluzinc steel coil.

Advantage:

- Strong corrosion resistance, 3 times that of galvanized steel sheet.

- The density of 55% aluminum is smaller than the density of zinc. When the weight is the same and the thickness of the plating layer is the same, the area of the galvalume steel sheet is 3% or larger than that of the galvanized steel sheet.