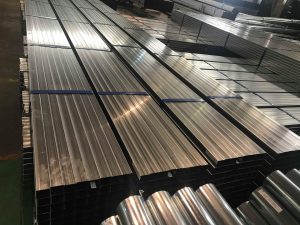

Galvanized Steel Pipe – HDGI pipe

Galvanized Steel Pipe – HDGI pipe

Hot dipped galvanized steel pipe is in manufacturing process using steel pipes of removed rust dipped into zinc liquid of 500℃ temperatures, and making steel surface attached zinc layer so as to achieve the purpose of anti-corrosion. Detailed Product Description: Capacity: About 40,000 Tons Per Month […]

Hot dipped galvanized steel pipe is in manufacturing process using steel pipes of removed rust dipped into zinc liquid of 500℃ temperatures, and making steel surface attached zinc layer so as to achieve the purpose of anti-corrosion.

Detailed Product Description:

Capacity: About 40,000 Tons Per Month Thickness: 0.7 – 2.50mm

Standard: JIS G3466 & G3444 Zinc Coating: 80g/m2-275g/m2

Usage: Constructions Packing per bundle: As customer request

Payment: T.T or LC At Sight Delievery: By Container Or By Bulk.

Certificate system: JIS G3466 & G3444 Origin : Nam Kim Steel – VietNam

Dominant characteristics:

– Especially produced for various usage purposes

– Long life of 4 times longer than other normal

– Effective corrosion sheets

– Good heat resistance

– The chormated, anti-finger layer is equipped:

– Stain-proof and oxidization resistance

– Keeping the surface of the products shiny for a long time

– To reduce cracking, scratching coating during stamping, rolling.

Applicant:

Galvanized steel pipe mainly used in transmission of coal gas, steam……. It was used as water pipe, but after several years past, there were many rust in the pipe, and water get yellow color for carrying iron oxide. The water not only polluted dishes or other sanitary ware, but also carrying bacteria produced in the internal surface which not smooth . As a result of the corrosion, the water contains heavy metal element is too much and is harmful to people’s health. For this reason, developed countries gradually banned it using as water pipe since 1960s.