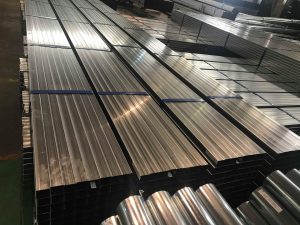

Pre-painted Al-Zinc Steel – PPGL

Pre-painted Al-Zinc Steel – PPGL

Pre-Painted Alu-Zinc is produced from the color coating line Input sheets are put into flushing, pickling phases and coated with an additives to enhance the adhesives, then, it is covered with the primer before it is officially painted and dried.

PPGL is generally used for the civil and industrial engineering industry (such as roofing plate, partitions, ceiling partition, rolling door, etc.) or industrial power (such as house, cover of electrical equipment, etc.) and interior decoration.

Pre-Painted Alu-Zinc is produced from the color coating line Input sheets are put into flushing, pickling phases and coated with an additives to enhance the adhesives, then, it is covered with the primer before it is officially painted and dried.

Capacity: 180,000 tons/years

Thickness: 0.23 ~ 1.2mm

Painting thickness: Min 15/5 microns, Max 30/20 microns

Paint supplier: Becker, KCC, PPG

Width: 914 ~ 1250 mm or Slitting. Al-Zinc coating: 40g/m2 ~ 150 g/m2

Coil Weight: 2 ~ 12 T Standard: IS G3321:2010 (Japan); BS EN 10346:2009 (Europe); AS 2728 (Australia); ASTM A755 (USA).

Coil ID: 508/610mm Color:All RAL colors or customized color

Merit: superior flatness & good thickness tolerance control

Siemens Automation Production capacity: 2 Pre-painting line

Base material: Al-Zinc steel coils

Applications of PPGL steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3. Transportation: oil tank; road sign; etc.